HP Multi Jet Fusion

CONTACT

MJF 3D PRINTING

The second half of the debate is MJF (HP multi jet fusion) 3D printing. In general 3D printing was used for prototyping and

product development, but with MJF technology it has evolved, it became an excellent solution for various fill-scale

manufacturing projects as well.

Unlike injection molding, MJF 3D printing doesn’t require additional set up costs or tooling, making it faster and a less

expensive resource for small to medium project units.

Furthermore it gives an almost absolute freedom of design and it boosts the time to market.

•

Almost total freedom of design

•

Time to market greatly improved

•

Extreme customization possible

•

Zero start-up costs

•

Economic advantage in many cases, why?

1.

Unique parts instead of separate parts for the

same object

2.

A new version of the part can be made without

additional costs

3.

The breakeven point can be very surprising

Time to Market:

MJF 3D printing is the answer

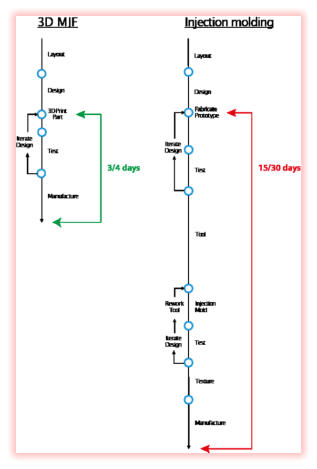

Time to market can be a decisive competitive advantage in a historical moment when

the average life of products is reduced and the end user is sensitive to delivery

times. Take a look at this comparison chart:

OPTIMIZATION:

The final design optimization for 3D printing is maintaining the third dimension and combining parts.

When a mechanical designer takes a system function and breaks this into parts that can be easily Injection Molded, the resulting parts are largely

2.5-dimensional, meaning that they tend to have two larger dimensions and one smaller dimension.

This is because molds must open and close easily. If you intend to 3D print the parts, the parts can remain integrated, and then the breakeven curve

becomes a comparison of one part versus several parts from several molds.

Injection molding > MJF 3D printing

Conclusion:

let's keep it short

In choosing which process to use for final part manufacturing of a specific part, it’s important to consider which may be the least expensive

combination of process and material that meets the design requirements.

Piasini Engineering S.a.s

Via Isole, 13 23020 - Piateda (SO) - Italia

Tel: +39 0342-48.90.60 | Fax: 0342-48.82.98

PEC : piasiniengineeringsas@legalmail.it

E-mail: info@piasiniengineering.it

Web: www.piasiniengineering.com

P.IVA & Cod. Fiscale : IT00902270149

HP Multi Jet

Fusion

MJF 3D PRINTING

The second half of the debate is MJF (HP multi

jet fusion) 3D printing. In general 3D printing

was used for prototyping and product

development, but with MJF technology it has

evolved, it became an excellent solution for

various fill-scale manufacturing projects as

well.

Unlike injection molding, MJF 3D printing

doesn’t require additional set up costs or

tooling, making it faster and a less expensive

resource for small to medium project units.

Furthermore it gives an almost absolute

freedom of design and it boosts the time to

market.

CONTACT

•

Almost total freedom of design

•

Time to market greatly improved

•

Extreme customization possible

•

Zero start-up costs

•

Economic advantage in many cases,

why?

1.

Unique parts instead of

separate parts for the same

object

2.

A new version of the part can

be made without additional

costs

3.

The breakeven point can be

very surprising

Time to Market:

MJF 3D printing

is the answer

Time to market can be a decisive competitive

advantage in a historical moment when the

average life of products is reduced and the

end user is sensitive to delivery times. Take a

look at this comparison chart:

OPTIMIZATION:

The final design optimization for 3D

printing is maintaining the third dimension

and combining parts.

When a mechanical designer takes a

system function and breaks this into parts

that can be easily Injection Molded, the

resulting parts are largely 2.5-dimensional,

meaning that they tend to have two larger

dimensions and one smaller dimension.

This is because molds must open and close

easily. If you intend to 3D print the parts,

the parts can remain integrated, and then

the breakeven curve becomes a

comparison of one part versus several

parts from several molds.

Injection molding > MJF 3D printing

Conclusion:

let's keep it short

In choosing which process to use for final part

manufacturing of a specific part, it’s important to

consider which may be the least expensive

combination of process and material that meets the

design requirements.

Piasini Engineering

S.a.s

Via Isole, 13 23020 - Piateda (SO) - Italia

Tel: +39 0342-48.90.60 | Fax: 0342-48.82.98

PEC : piasiniengineeringsas@legalmail.it

E-mail: info@piasiniengineering.it

Web: www.piasiniengineering.com

P.IVA & Cod. Fiscale : IT00902270149

PIASINI ENGINEERING. All right reserved. | Contact us per Email: info@piasiniengineering.it | Follow us by

PRIVACY | COOKIE

PIASINI ENGINEERING. All right reserved.

Contact us per Email: info@piasiniengineering.it

PRIVACY | COOKIE